Initiatives for the natural environment

At our factory in Akabira, Hokkaido, we are working on the following activities as environmentally responsible actions: recycling shells of suitcases, reducing CO2 emitted by running factory, saving energy, etc.

Through taking eco-friendly methods and techniques into our manufacturing lines, we're trying to keep that people can experience four seasons and see picturesque landscapes of various locations in a beautiful island nation, Japan as a tourist attraction forever.

Then, from small, we diligently contribute to the natural environment protection.

Even if it's small, we can steadily incorporate methods and techniques that are kind to the natural environment into manufacturing, so that Japan, a beautiful island country, can continue to be a tourist destination where you can enjoy the colors of the four seasons and the unique scenery of each region. We will work to protect the natural environment.

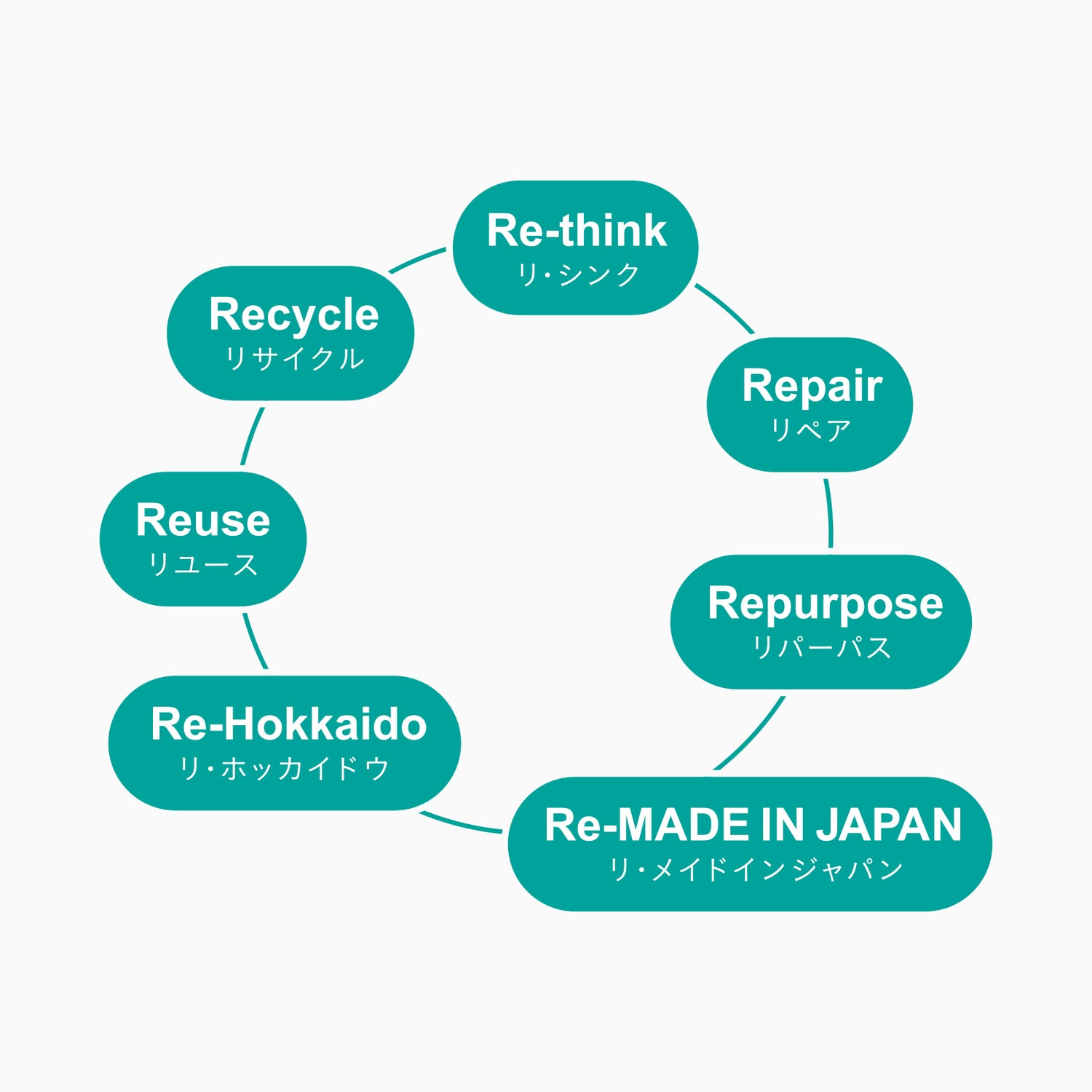

ACE LUGGAGE "7R"

At ACE Luggage, we have established the "7 R's" and are developing products that fall under any of them.

-

Re-MADE IN JAPAN

We aim to connect Japanese industries with Made in Japan, and aim for sustainable social activities by viewing local production for local consumption in a broad sense.

-

Recycle

We are working to use recycled materials and collect and recycle ACE Luggage products.

-

Reuse

Think before you throw away - We strive for multiple reuse of materials and products.

-

Repair

We strive to repair products that our customers have used for many years so that they can continue to use them.

-

Re-think

In order to protect the future of the earth, we will reconsider our actions and strive to be environmentally friendly from wherever we can.

-

Repurpose

We upcycle items to increase their value again through repair and reuse.

-

Re-Hokkaido

We manufacture products with the scent of Hokkaido at our factory in Akabira City, Hokkaido.

Hard-Shell Suitcase Resources Recycling

We collect scraps generated during the manufacturing process of shells of hard-shell suitcases and use them as recycled resources. This resource circulation has continued since our establishment in 1960.

After finely grind, the scraps of the main body shell are made into plates again and reborn into new suitcases.

We mainly use recycled materials and new materials in the form of two-layer sheets, with a recycled material usage rate of approximately 50%. This formulation has a proven track record of producing high-quality products for many years, maintaining a balance between strength and flexibility.

Reuse of materials for bags and accessories

Reusing waste materials of Tokaido Shinkansen

We create upcycled items using scrap materials of the retired Tokaido Shinkansen N700 series typeA. We are reconsidering the idea of "throwing away" and working to reborn it into new products.